- The incorporation of polyester into the cotton weave enhances the sheet's resistance to wear and tear, ensuring they remain soft and resilient for an extended period. Unlike pure cotton sheets that can show signs of thinning or fraying after repeated washes, poly cotton blends maintain their robust texture with minimal pilling or shrinkage. This makes them an excellent long-term investment for those seeking bedding that stands the test of time.

When choosing bedsheets, it is important to consider factors such as material, weave, thread count, and care instructions. If softness and warmth are your priority, flannel sheets may be your best choice. For a silky, luxurious feel, satin or satin sheets may be the perfect choice. If breathability and durability are your top priorities, cotton sheets may best suit your needs.

Cotton

It would seem that the duvet continued to be used by Europeans, for in the 18th century, Thomas Nugent, an English writer included in his European travel book ‘The Grand Tour’ a description of what appears to be a duvet whilst in the German state of Westphalia.

When researching bedding production, it pays to look for a reputable bedsheet manufacturer known for its expertise in producing high-quality bedding. Bedsheet manufacturers with a proven track record in producing flannel sheets are more likely to offer products that meet the highest standards.

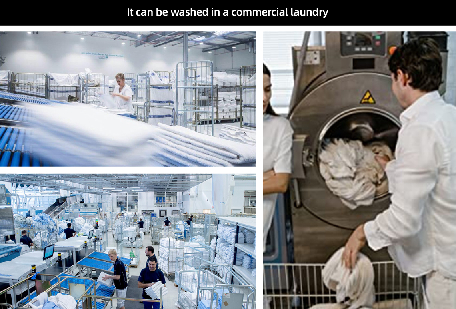

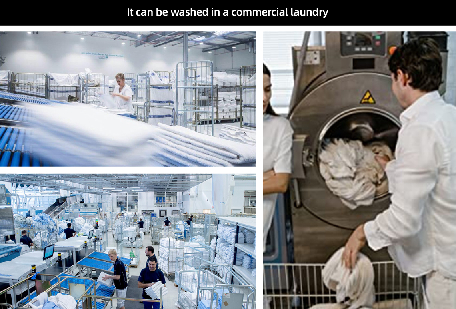

It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details

It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details plain towel. This practicality makes it a favorite among busy households and those who appreciate the ease of maintenance.

plain towel. This practicality makes it a favorite among busy households and those who appreciate the ease of maintenance.

Hotel towels are usually made from high-quality materials to ensure durability and absorbency. The most common materials used for hotel towels include cotton, microfiber, and blends of cotton and polyester.

In addition to the yarn count, the hotel sheets fabric used is also crucial. Cotton is the most popular choice for hotel sheets because of its breathability, softness, and durability. Egyptian or Pima cotton is often favored for its long fibers, which make hotel sheets finer, smoother, and more luxurious. Not only are these high-quality cotton hotel sheets comfortable, they stand up to frequent washing and retain their softness over time.